|

|

|

| The hive is built out of red oak. The

white circles on the back of the hive are plastic air vents. There are

also four of them on the front (towards the window). the building's

window was replaced with Plexiglas and a hole cut through it allowing the

clear PVC tube entrance tube to pass through. The entrance is just

above the top frame of bees. There is a groove cut in

the board at the base, which allows the bees to pass to the feeder area.

The whole hive is bolted to the table, and the table is fastened to the wall

to prevent it from tipping. The following

section shows a little how the hive works and how it is taken apart for

working with the bees: |

|

|

|

| First, the the top (outer

cover) must be removed. It is screwed on using four square-headed

finish screws. The top just sits above the hive's inner cover. |

|

|

|

| Next, the back (away from

the window) must come off. The back is held in place with two square

head finish screws at the bottom and the screws that hold the top (outer

cover) on also hold the back on. The individual frame modules fit into

a groove that I dadoed into each the back and the front (towards the

window). Also, each module has a hole drilled into the end which lines

up with the plastic vents on the front and back. The modules then have

a piece of screen stapled over each vent hole. Each module is open at

the top and the bottom to allow the bees to travel between the different

frames. The top frame has an inner cover over it, which keeps the bees

from escaping out of the top and also allows access to the entrance tube. |

|

|

|

| Then I slide a U-shaped

piece of aluminum flashing into the crack between the top and the 2nd

modules (above left). This separates the top of the hive (and the

entrance) from the rest of the hive. In this picture, I put the first

flashing in with the "U" facing down, but it doesn't matter which one is

inserted first. After the first piece of flashing is inserted, I

insert a second piece above it (with the "U" facing up)(above middle).

The flashing is held in place with just the force of the bend in the

flashing squeezing the module. the top piece of flashing prevents the

bees from moving down out of the top module and the bottom piece prevents

the bees from moving up out of the rest of the hive. Another piece of

flashing bent to fit into the dadoed groove in the front (toward the window)

is inserted between the front and the top module (above right) and is held

to the front. A piece of flashing is also bent to cover up the

entrance hole in the inner cover on top of the top module (not shown) to

prevent the bees from escaping while the module is removed. |

|

|

|

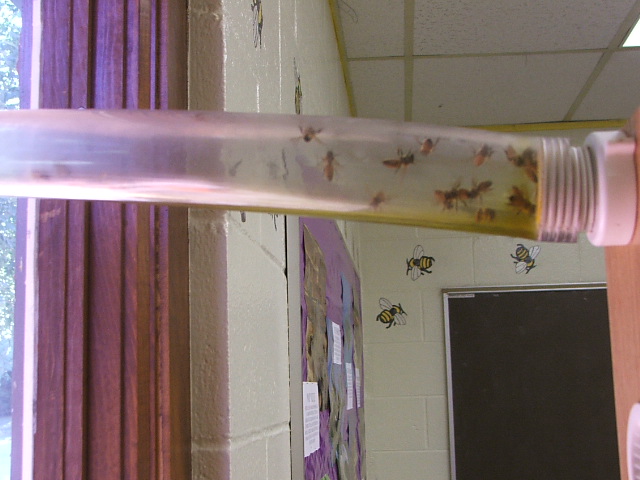

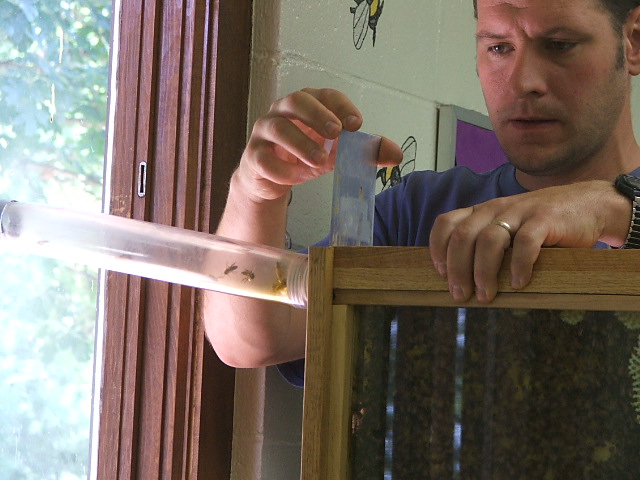

| At this point, the bees are

entirely contained in the hive. The top module can be carefully

removed (left). The center picture (above) shows the inside of the

front (toward the window) with the flashing piece covering the entrance.

Since many bees were out foraging at the time the entrance was covered, they

tend to fill the tube waiting to come back in (right). the dado in the

front piece can also be seen here. |

|

|

|

| Flashing pieces are then

inserted between the second from the top and third frames and the send frame

can be removed (left). Right hand picture shows the top two frames in

the room with no bees flying around! |

|

|

|

| Above pictures show the

bottom two frames in place with the top frames removed. The middle

picture also shows one of the flashing divider pieces upside down on the

table. Meanwhile, the foraging bees have filled the tube and are

clustered outside on the entrance (right). |

| I have enough flashing to

allow me to remove the top three frame modules at one time. I then

suit up and take the modules outside the window to work them. I

usually remove the flashing divider, then remove the frame, then scrape the

glass with a hive tool to remove burr comb. While they are outside, I

can take the flashing divider back inside to remove the bottom module.

During removal of the bottom frame, it is possible for a small number of

bees to escape, since some may be in the area of the sugar syrup feeder,

which I have not found a way to close off yet. |

| I put the hive back together

in the opposite order. The only difference is that I often stack two

modules together outside and bring them in as a pair with the flashing

dividers covering the top opening and bottom opening. The modules can

also be removed two at a time, but they tend to get heavy very quickly! |

|

|

|

| By the time the entrance is

once again opened, the bees have already clustered all over the window

(left). The hive is back together (right) except the back and the top

(outer cover) need to be screwed back on. |

| I am experimenting with the

top frame. I modified a frame by angling the top bar. I then put

a 1" strip of foundation in. The idea is that the bees will start

drawing out the comb at the top and will continue without foundation.

This encourages the bees to draw out natural size cells, rather than the

size specified by the foundation. So far, they aren't drawing much of

it out, but the jury is still out. |